PFC/PFAS decontamination

Pioneer in process technology progress

Your solution for effective PFC/PFAS decontamination

Our advanced decontamination process eliminates PFC/PFAS from facilities and environments. With our innovative approach and strict control mechanisms, we not only ensure the removal of currently controlled substances, but also prevent future contamination.

Your advantages with us:

- Detection limit not exceeded

- No residue

- Fast procedures

Let us advise you without obligation

That's what you get with us:

Comprehensive analytics

Our precision analytics ensure that every step of the decontamination process is accurately documented and monitored to guarantee the highest standards of purity and safety.

Immediate operational readiness

Once decontamination is complete, we guarantee that your systems will be up and running again quickly, minimizing downtimes and thus increasing your productivity.

Certified quality

All processes and results are certified according to the strictest industry standards, providing you and your stakeholders with additional security.

Environmental protection

Our process protects the environment and helps to preserve biodiversity and natural resources for future generations.

Sustainable practices

We use the latest, environmentally friendly technologies and materials to minimize the ecological footprint of our services.

Individual customer service

Every customer receives advice tailored to their specific needs to ensure optimum results.

Why we're a leader:

A superior alternative

Our company occupies a leading position in the decontamination industry – and for good reason. While some are content with superficial approaches, we focus on innovative, efficient and environmentally conscious processes.

1. scientifically sound methods

2. Environmental awareness

3. Customized Services

4. Transparent processes

5. Proven superior results

New system or decontamination with us?

Before you invest in a completely new facility, consider the benefits of our decontamination services. While a new facility can seem tempting, the associated costs and time involved are enormous.

Our decontamination offers an efficient and cost-effective alternative that allows you to maximize your existing resources while minimizing environmental impact.

The costs for decontamination are generally significantly lower than building a new plant.

Decontamination can be carried out in a fraction of the time it would take to build a new plant.

solutions

Our decontamination processes are highly customizable.

In addition to one-off decontamination, we also offer ongoing maintenance contracts.

Sustainable decontamination: an indispensable measure for long-term environmental protection

Decontamination is a continuous and long-term challenge for companies. It is inevitable that investment in efficient and sustainable technologies is required not only as a preventative measure, but also as a future-proofing strategy.

These technologies are crucial to meet the increasing environmental requirements and legal regulations. Therefore, recurring cleaning measures are not only unavoidable, but also essential for maintaining the operational capability and safety of the systems.

Continuous research and development play a key role in harnessing technological advances and providing effective decontamination solutions.

Request a non-binding offer now

If you are looking for a reliable partner for the maintenance and cleaning of your silo systems, NT Service GmbH is the right address for you.

Frequently asked questions about PFC/PFAS decontamination

What are PFCs or PFAS and why is their decontamination important?

- PFCs (perfluorocarbons) and PFAS (per- and polyfluorinated alkyl substances) are synthetic chemicals that are used in many everyday products, such as: B. in textiles, coatings, fire extinguishing foam and electronics.

- Due to their longevity and resistance to degradation, PFCs/PFAS accumulate in the environment and the food chain, where they can have negative impacts on human health and the environment.

- Decontamination of PFCs/PFAS is therefore important to reduce environmental pollution, protect drinking water quality and preserve people’s health.

What techniques are used to decontaminate PFCs/PFAS?

- Activated carbon filtration: Activated carbon binds PFCs/PFAS molecules to its surface and thus filters them out of the water.

- Ion exchange: Ion exchange resins exchange ions in the water matrix for PFCs/PFAS ions, thereby removing them from the water.

- Advanced Oxidation Processes (AOP): AOP processes use high-energy oxidants such as ozone or hydrogen peroxide to break down PFCs/PFAS molecules into harmless byproducts.

- The choice of the appropriate decontamination technique depends on various factors, such as: B. the type and concentration of PFCs/PFAS, the size and type of the contaminated facility and the legal requirements.

Are there legal requirements for the removal of PFCs/PFAS?

Yes, the regulation of PFCs/PFAS has become increasingly stringent in recent years due to growing concerns about their environmental impact and health risks. Many countries have introduced limits for PFCs/PFAS in drinking water, soil and air. In addition, there are industry and facility-specific regulations for the decontamination of PFCs/PFAS. It is important to find out about the applicable laws and regulations in the respective region before carrying out a decontamination measure.

How often does a PFC/PFAS removal system need to be serviced?

The maintenance frequency of a PFC/PFAS decontamination plant depends on various factors, such as the type of plant, the quantity and concentration of PFCs/PFAS, the operating time and local legislation. In general, however, it is important to carry out regular maintenance and inspections of the system to ensure that it is functioning optimally and effectively reducing PFC/PFAS concentrations. Maintenance intervals can vary from a few months to several years. It is important to follow the equipment manufacturer’s recommendations and create a maintenance schedule that meets the specific requirements of the equipment and local regulations.

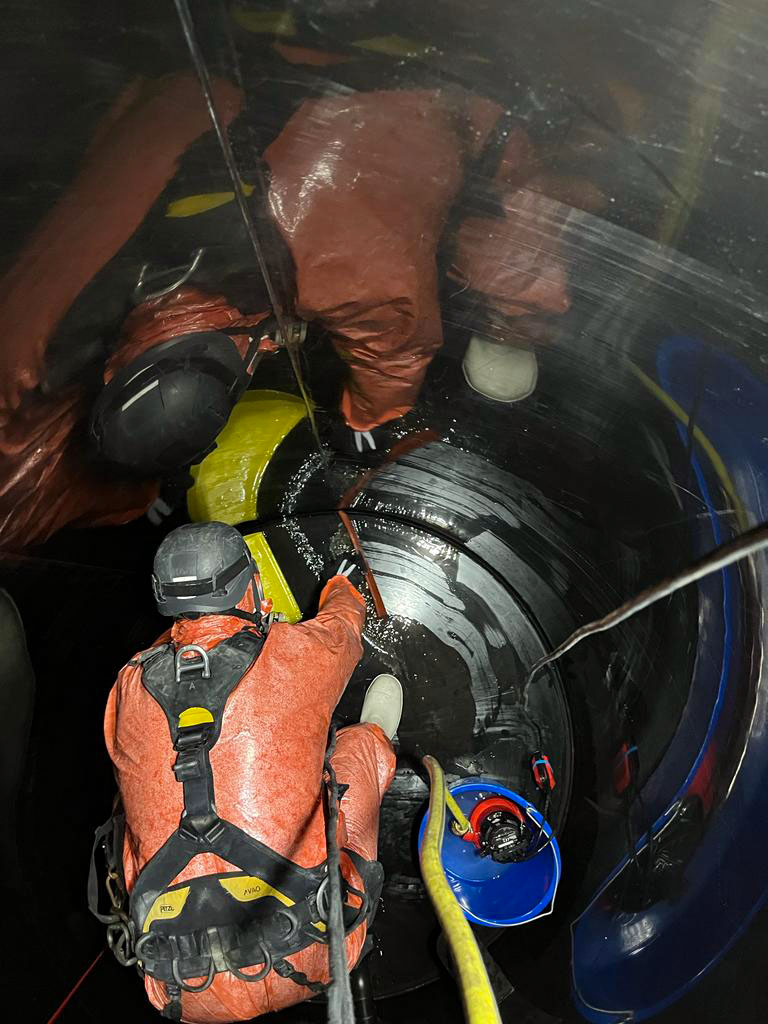

What safety precautions does TNT Reinigung Service take to protect its employees?

- Comprehensive security measures: TNT Cleaning Service relies on a multi-level security system to protect its employees. This includes regular training, strict compliance with all health and safety regulations and the provision of personal protective equipment (PPE) for all employees.

- Regular training: All employees undergo regular training on relevant safety standards, emergency procedures and the proper use of cleaning chemicals. This ensures that every employee is always informed about the current safety regulations and can apply them correctly.

- Strict compliance with occupational health and safety regulations: TNT Cleaning Service strictly adheres to all applicable occupational health and safety regulations and guidelines. This includes both legal requirements and the company’s internal security standards.

- Personal Protective Equipment (PPE): All employees are provided with the necessary PPE to protect them from hazards during their work. This may include gloves, goggles, respirators and other protective equipment.

What measures are taken to minimize the health risks from handling chemicals?

- Risk assessment and risk assessment: TNT Cleaning Service regularly carries out risk assessments and risk assessments to identify the potential health risks when working with Identify chemicals.

- Selection of harmless chemicals: When selecting cleaning agents and other chemicals, TNT Cleaning Service always pays attention to those that are as environmentally friendly and health-friendly as possible harmless products.

- Instruction and training: All employees who come into contact with chemicals are fully informed about the associated risks and trained in safe handling.

- Personal Protective Equipment (PPE):When working with chemicals, the use of PPE such as gloves, goggles and respirators is recommended mandatory.

- Regular health checks: For employees who regularly work with dangerous substances, TNT Cleaning Service offers regular medical examinations, to monitor their health and detect possible effects from contact with harmful chemicals at an early stage.

How is compliance with the safety guidelines monitored at TNT Reinigung Service?

- Regular internal reviews: TNT Cleaning Service periodically conducts internal reviews to ensure everyone’s compliance with security policies to ensure employees. These checks can be carried out randomly or on an ad hoc basis.

- External audits: In addition to internal audits, TNTreinigung Service also regularly has external audits carried out by independent experts. This helps to objectify the effectiveness of the company’s occupational health and safety management system and to identify potential for improvement.

- Safety officer:The company has a safety officer who is responsible for monitoring workplace safety and conducting risk assessments . The safety officer is the contact person for all employees regarding occupational safety issues and can provide advice and support if necessary.