Sandblasting of tanks and silo systems

With our state-of-the-art sandblasting technology, we effortlessly remove stubborn deposits and dirt to restore your systems to top condition.

Rely on our expertise and state-of-the-art equipment to ensure thorough and effective cleaning.

Your specialist for sandblasting tanks and silo systems

Silo systems and tank systems are successfully and gently blasted by our technicians. The aim is to gently and successfully remove difficult-to-remove adhesions. If necessary, the surface to be blasted is prepared for internal tank coating, which we can also offer.

We have been working with Sika for many years on coating the inside of tanks and silos. One of the best coating manufacturers in the world.

Our sandblasting application is carried out without the use of scaffolding. We work exclusively on the rope in your silo and tank system using the application method.

The advantages of sandblasting

In addition to gentle surface treatment, this blasting process offers the following advantages:

Effective cleaning

Sandblasting offers an extremely effective cleaning method for silos and tanks, as it thoroughly removes stubborn dirt, rust, old coatings and other contaminants.

Environmentally friendly

Unlike some chemical cleaning methods, sandblasting is environmentally friendly and produces no harmful fumes or residues. It simply uses sand or other environmentally friendly abrasives to clean the surface.

Increased service life

By removing rust, old coatings and other contaminants, silos and tanks can be restored to their original condition by sandblasting. This helps to extend the service life of the systems and improve their performance.

State-of-the-art technology for excellent sandblasting results

To ensure high-quality sandblasting work, suppliers should be equipped with the latest and most sophisticated technology. In this way, customer requests for sandblasting on a contract basis can be carried out on time and to the highest quality standards. In this context, important machine parts and complex constructions, which have to be processed internally regardless, are usually sandblasted by hand.

Quality features for sandblasting

Certified contract sandblasting suppliers blast according to precisely defined work steps and computerized processing parameters.

This also ensures that the sandblasted parts meet the same high standards for large quantities. In all of this, the desired degree of cleaning is determined before processing in the client’s sandblasting shop.

These are

SA 1

Sandblasting with a brush-like cleaning effect

SA 2

Normal surface cleaning without high-gloss effect

SA 2 1/2

Cleaning down to a bare metal surface in the same way

SA 3

Cleaning down to a completely bare metal surface

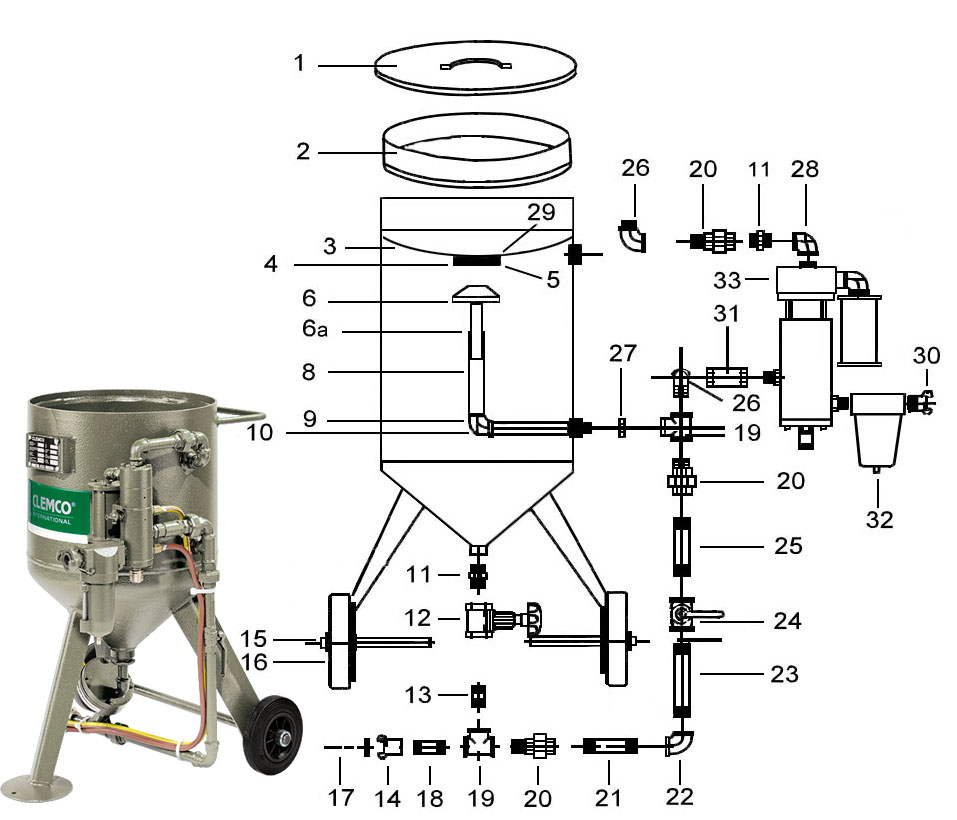

Our applied blasting technology

The blast pot forms the heart of the pressure blasting system. It is crucial to consider the correct configuration and compatibility of the machine components to ensure maximum blasting efficiency.

Thanks to many years of experience and innovation, Clemco products guarantee high reliability, durability and safety for abrasive blasting.

Request a non-binding offer now

If you are looking for a reliable partner for the maintenance and cleaning of your silo systems, NT Service GmbH is the right address for you.

Frequently asked questions about sandblasting

What is sandblasting?

Sandblasting is a technological process for abrasive surface treatment and is intended for cleaning metal surfaces and matting glass. Sandblasting of metals fulfills a dual function, as the surfaces are both cleaned and roughened.

This blasting effect is achieved by blasting agents such as corundum or garnet sand, which hit the surface at high speed and thus clean and roughen the metal surfaces in a single treatment process. I

n this context, the surface structure is determined by the abrasive used and the degree of cleaning depends on the subsequent surface protection required.

How does sandblasting work?

During the blasting process, a strong jet of air is generated, which is mixed with an abrasive. The required air pressure is generated by specific compressors and the powder-like blasting agent can be either dry or mixed with water from a collection container.

This special sand-air mixture is then blasted onto the surface to be treated at high speed via a hose and nozzle system. In this process, surface particles are loosened due to the abrasive blasting effect and then removed.

In this way, surfaces are thoroughly cleaned of impurities, rust, paint or scale. Depending on the process, different degrees of cleaning can be achieved.

Where is sandblasting used?

Different materials can be processed with sand or other blasting agents, from metals to stone and glass. Surface finishing with fine blasting creates a roughened, matt surface. Metals and glass are primarily processed in this way.

Sandblasting on a contract basis can be used for a wide range of applications. In addition to cleaning and restoration work, blasting technology is used for surface finishes and fine blasting for surface optimization. As a result, contract sandblasting has become an important basic technology for a wide variety of manufacturing industries.

Cleaning work

Surface optimization

Restoration work

Matting of glass

What sandblasting methods are there?

Depending on the material to be blasted and the desired requirements, different processes are used when blasting with sand.

What does sandblasting mean in terms of wages?

Sandblasting on a contract basis is a surface treatment that is carried out on behalf of special manufacturing companies. With the help of this process, workpiece surfaces are perfectly cleaned of rust, scale, varnish and paint residues. Metal blasting fulfills a dual function within all of this. On the one hand, metallic surfaces are cleaned and roughened in the same work step. During the blasting process, blasting media is directed onto the surface of the workpiece to be treated at high speed using a compressor. In this way, surfaces can be cleaned, roughened or matted of their own or foreign debris.