Polyester silo systems are repaired and inspected by our specialists – Silo polyestering is the term for thermal bonding and repair work on the silo inner wall and cone outlet.

Polyester silo systems have many advantages in bulk material storage, which we would like to highlight in this article. Polyester silo systems are made from special glass fiber, which offer high mechanical resistance and excellent thermal insulation. Light, hermetic and tightly sealed joints ensure long-lasting bulk material storage.

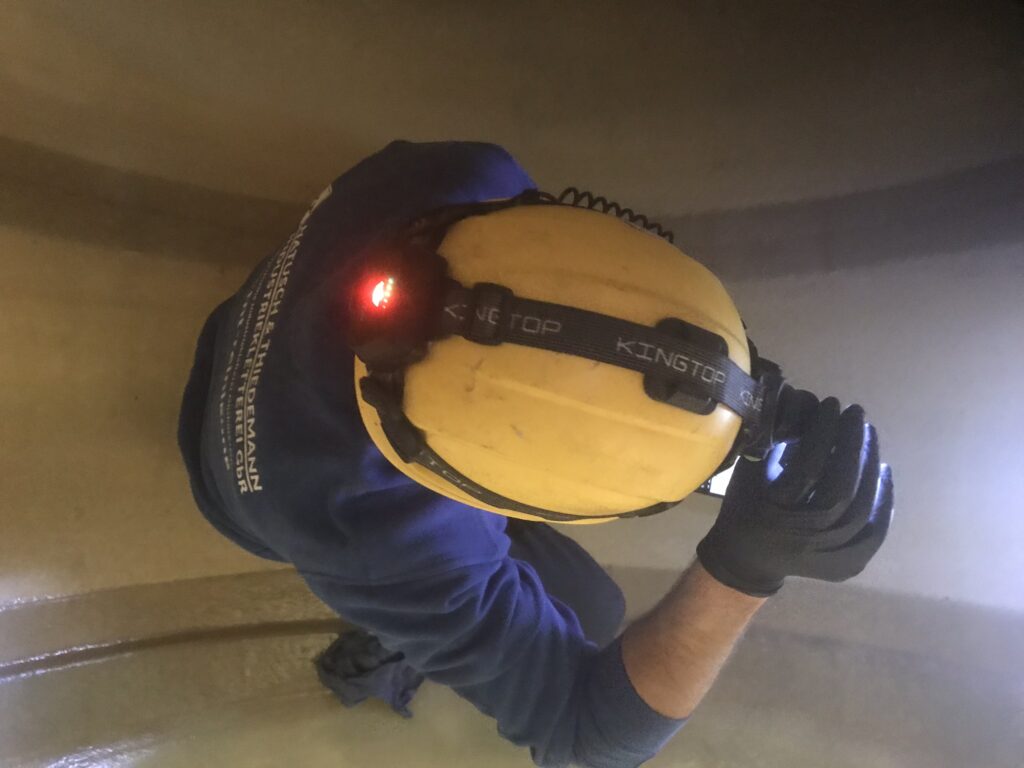

According to Mosh, however, these tend to become unstable in continuous use in terms of abrasive mechanics. The bulk materials should be assessed according to their abrasiveness in order to avoid subsequent damage to the silo wall in any case. We carry out the repair of this silo system construction using rope technology, quickly and extremely inexpensively. Before the repair, however, an extensive internal silo cleaning is necessary so that further damage can be more easily identified by the inspector.

Regular silo cleaning is also recommended in any case. We offer repairs for small damaged areas as an inclusive service with silo cleaning.

Highly abrasive materials or bulk goods that can take on abrasive structures due to their clumping properties should be stored carefully in polyester silo systems. A regular internal silo inspection is expressly recommended and, with little financial outlay, is in any case cheaper than a complete silo repair.